KADLEC - KOVOVÝROBA

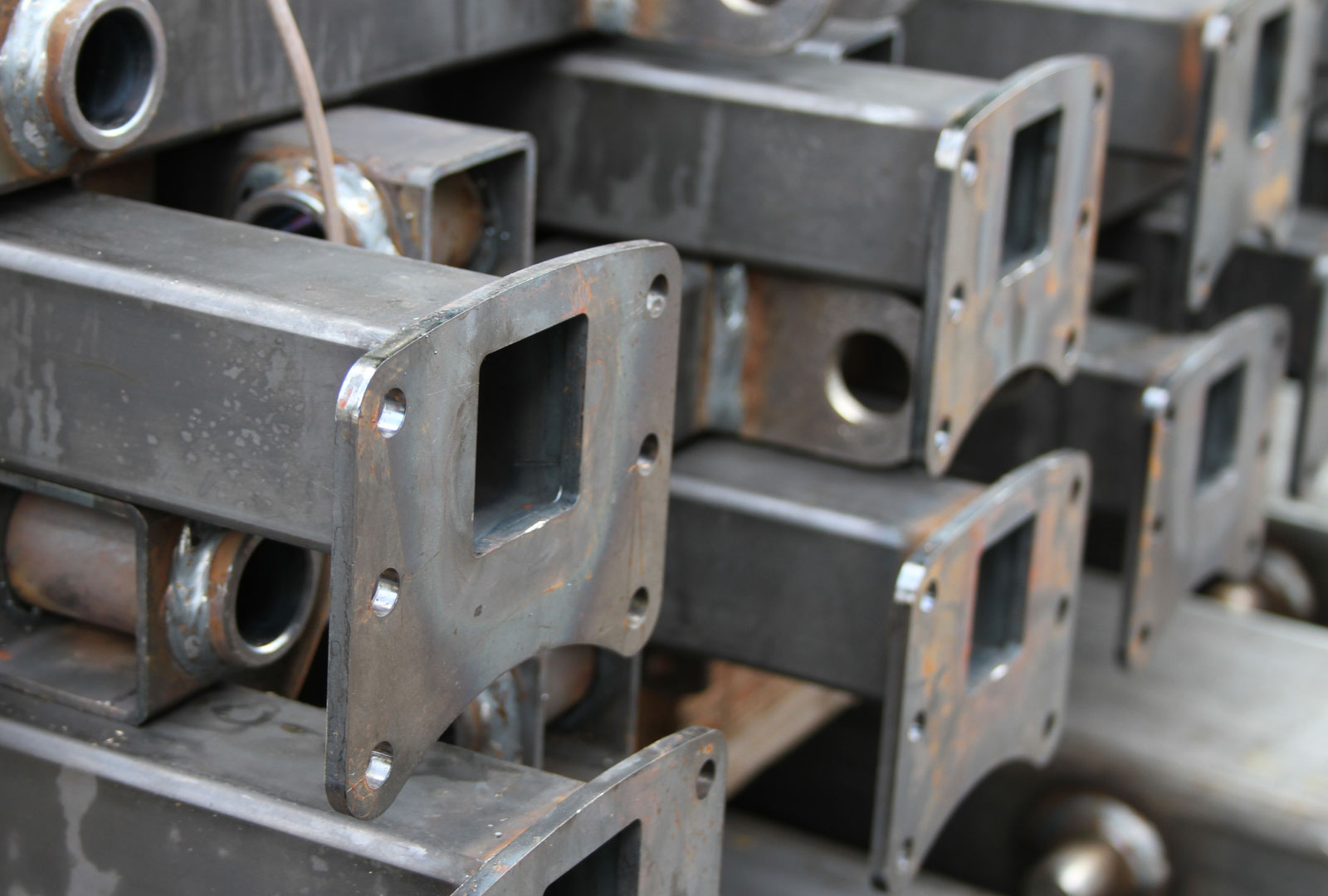

Company Kadlec Lts. was established by Mr. Bohuslav Kadles more than 22 years ago as a tractor depot centre in Turnov. A family company Kadlec Ltd. has dealt with the metalworking more than 20 years – already from the small machine parts to the big welded and assembled bodies both for home and foreign trade. From several employees at the beginning, the company has grew into its nowadays size and has over 60 regular employees. Basic portfolio of producing parts consists of welded and assembled bodies including surface treatments for agriculture, forestry and building machinery.

At production, company Kadlec Ltd. puts the accent on the quality and precise processing of the producing parts. Nowadays is our company focused on the export sale (more than 90%) and its products are delivered into several European countries. Surely, company Kadlec Ltd. is certificated acc. to ČSN EN ISO 9001:2016 and welders are certificated acc. to EN 287-1:2012. Long-term experience in the branch and workers responsibility ensures the high quality of production. Company machine equipment is focused on the single-part and small batch production with the high variability of produced parts which makes possible to flexible react on the requirements from our customers. Communication can be done in German, eventually in English.

PRODCUTION CAPACITY OF THE COMPANY.

- Annually there is processed c. 1000 tons of material in the company Kadlec Ltd. As a basic production capacity there are:

- CNC plasma cutting (2500 x 6000 x 40) mm, hand plasma cutting to the s = 15 mm

- Automatic band saws and friction saws

- Plate shear s = 6 mm

- Eccentric and hydraulic presses, to the 2500 kN

- CNC press brake – 4000 mm / 3530 kN, 3000 mm / 1600 kN

- 4-roll bending machine 2500 mm

- Hydraulic bending machine for rods, tubes (max. ø 70 mm)

- 10 welding workshops, 3 mobile workshops (CEBORA MIG STAR)

- Shot blasting and painting box (7000 x 4000 x 4000) mm – wet paint shop

- Machinery shop – grinding machines, lathes (both conventional and CNC´s), (ø 500 x l = 1000) mm horizontal boring machine WH 80, milling machines and so on.

- Tool shop –for own needs and small orders

- Stock of the technical gases - AIR PRODUCTS

Moreover, considering the long-term good standing of a company in the market-place we also provide:

- Cutting of materials (steels, Al alloys, plastics and so on) by plasma jet and water jet cutting

- Powder coating

- Testing the materials mechanical properties, technological tests, dynamic tests, tribological testing of lubricants and substrates, tests of strength and resistance of adhesive bondings

- Development and construction of the machines and equipment, development and adjustment of the technological lines

- Construction of assembly and production jigs, construction of stamping tool including their checkout, construction of the moulds for injection, blowing and thermoforming of thermoplastics